|

Basic alloys (chemical composition uni |

Physical estate

|

|

3005 – 3105 – |

H42 – H44 – H46 – H47 |

Allowancetolerance

width

|

35-200 mm |

201-350 mm |

351-600 mm |

601-900 mm |

901-1500 mm |

|

+/-0.2 |

+/-0.3 |

+/-0.5 |

+/-1.0 |

+/-1.5 |

Thickness (without paint)

|

Punctual |

Average* |

|

0.200 -1.500 mm |

0.200 -1.500 mm |

|

+/- 8% |

+/-6% |

*:average

tickness =(D2-d2)xp/(4000xL)

D= outside diameter mm; d= inside diameter mm; L= length mt.

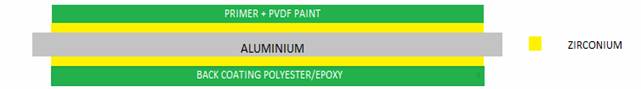

Chemical pre-treatment

Before being painted, the aluminium

undergoes two chemical degreasing processes and the zirconium treatment

Paint features

|

Painted |

Type of resin |

Film basis weight |

Film thickess |

Gloss |

|

|

|

≈30 g/m2 |

≈24 |

|

|

|

Back coating polyester/epoxy |

≈ ‚ 5 g/m2 |

≈4 |

30-90° |

Technical characteristics of the painted surface

|

Adherance |

AICC n°7 (checks method) |

|

|

Resistance |

100 double shots |

|

|

T bend test |

0T |

|

|

Shot at50 cm |

ok |

|

|

Glosstest |

Unit 10 20-39 |

Tolerance +/-3 +/-5 |

|

Colourmeasure |

White ΔE ≤ Pastel colour ΔE Metallic Colour ΔE |

|

|

Saline |

Depending on basic alloys used (astm |

|

|

Saline |

Depending on basic alloys used |

|

|

U.V. |

Good (1000 h) |

|

|

Reaction to fire |

A1 (EN 13501-1-2018) |

|

Painted according to UNI EN 1396

Protective film features: protective

film50/70 micron UV resistant